Spark and ember detection and suppression systems for machine ducts, chutes and conveyors.

In a robust fire safety environment, spark and ember detection and suppression systems identify potential ignition sources in materials or machine compartments in a process flow.

When a potentially dangerous particle is identified, the system immediately triggers, suppressing the risk before it can ignite surrounding materials or machinery.

Spark and ember detection systems extinguish a potential fire before it starts.

Fire Shield Systems offers bespoke spark and ember systems which are accredited by international regulatory bodies and other third-parties recognised by insurers.

Request a Quote Today!

How do spark detection systems work?

- An infrared spark detector is installed in the machine’s pneumatic conveying duct, chute or conveyor.

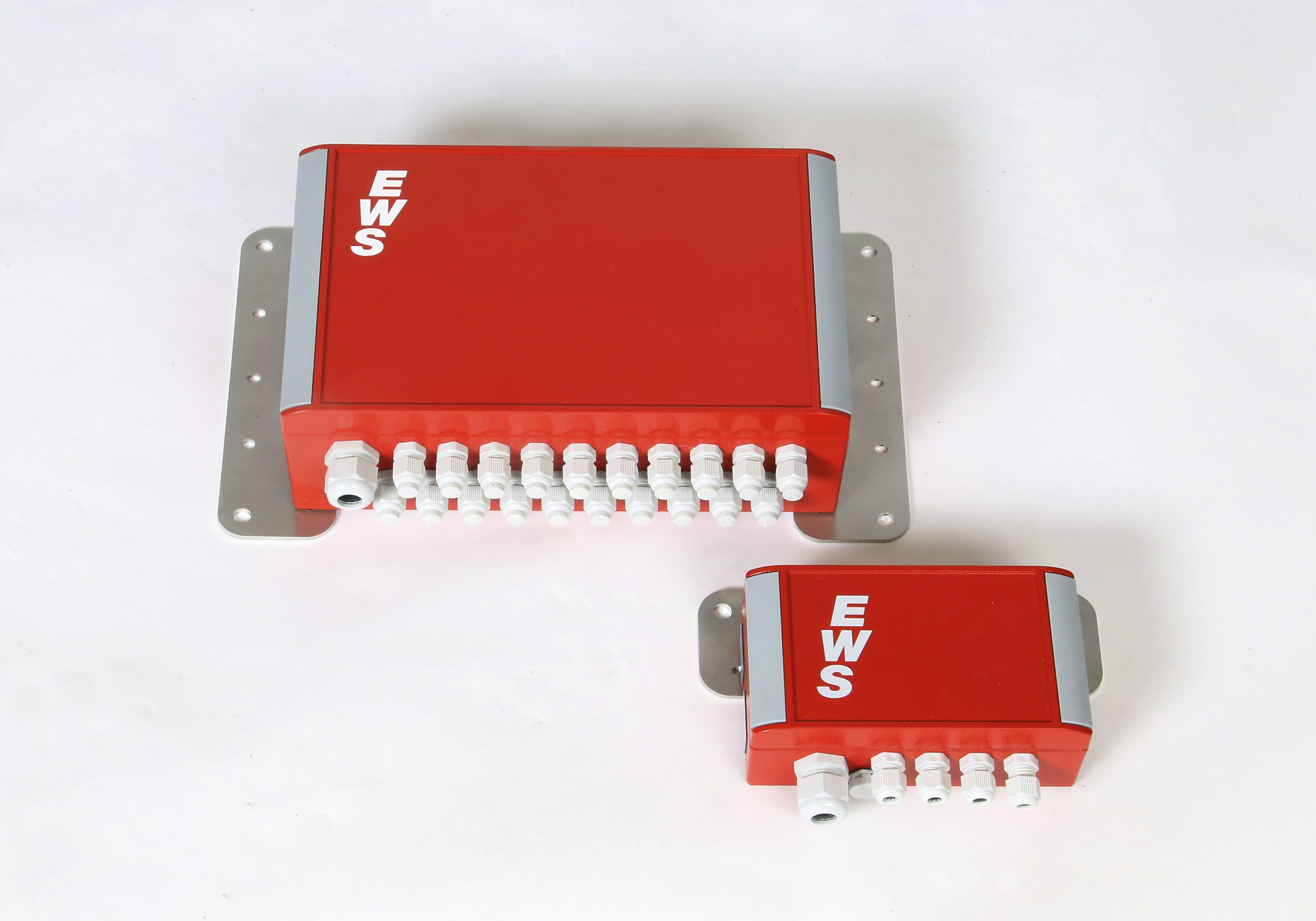

- This is connected to a control panel, which processes and stores all detected signals.

- When a spark is identified, the detector signals the suppression system, which is located further down the processing line. The system then releases an extinguishing agent: either water mist or a suitable alternative, depending on the material(s) being processed.

- This suppresses the spark, before it has chance to ignite surrounding materials or valuable machinery.

When do I need a spark and ember detection system?

Spark detection and suppression systems are used in processes where sparks, glowing particles or other flash points may be conveyed into dust filters or other plant units, where combustible materials are highly susceptible to ignition.

If left unprotected, a tiny spark can:

-

- Endanger your team

- Ignite a fire or explosion

- Halt production and process lines

- Damage or destroy assets (machines, stock, facilities, etc).

Where are spark and ember systems most effective?

Spark and ember detection systems are most commonly used on:

- Process extraction ducts, which lead to a dust filter.

- Enclosed plant configurations, where the fibres, chips and dust being transported have the potential to ignite.

Spark and ember systems should be used in conjunction with complementary protection methods, such as fire detection systems, to ensure maximum safety and minimum risk.

Get in touch

Want to know more about spark and ember systems and how they could protect your business?

Call 0800 975 5767 or fill in this form and a member of the team will look after you.