Technical Director Russell Bonnett and Sales Director, James Mountain of Fire Shield Systems discuss how targeted design supports early detection, effective suppression and alignment with Environment Agency and insurance standards

Waste and recycling facilities pose some of the toughest fire protection challenges in industry. Large volumes of combustible material, shifting fuel loads and constant mechanical movement create unpredictable ignition risks that few conventional systems can handle effectively. Fire Shield Systems Ltd, based in the East Midlands and operating across the UK and Ireland, designs and installs automatic fire suppression systems built for these demanding environments. To explore how Fire Shield is advancing performance-based fire protection for high-risk industries, IFSJ Editor Iain Hoey sat down with Technical Director Russell Bonnett and Sales Director James Mountain to discuss their approach.

What are some of the main challenges that make waste and recycling sites particularly difficult to protect from fire?

Russell: In many commercial and industrial applications, you install a fire suppression system, service it routinely and all being well the system is never called upon on a real fire scenario. Waste and recycling is different. These are harsh environments with material from many streams, including things operators weren’t necessarily anticipating. Our systems are challenged regularly because they’re frequently put into fire conditions, so activations are common. There’s also sometimes the challenges of high staff turnover and a lot of different languages on site, so the requirement for training is ongoing. Hardware can get hit or damaged by operators and site IT networks can become. “These are harsh environments with material from many streams, including things operators weren’t expecting.” industries smarter high-risk 64 November 2025 compromised either internally or by external “bad actors”. We work hard to support customers with quality management and training so clients fully understand what the system is there to do and to make sure that it remains operational at all times with the inbuilt monitoring and automated safeguards around power, communication and automation functionality.

James: Another challenge is change on site. We design to the brief we’re given, then when returning to site to review the requirement often find storage piles or processing areas might have changed or exceed the original design. We push for ongoing dialogue so if the risk evolves, the system is designed to be able to evolve and adapt with them. Housekeeping is huge. Waste keeps coming in even during a breakdown, so piles grow therefore sites can become non-compliant because too much waste is being stored beyond the permitted quantity. The result of this is that the system can potentially be compromised. The less waste sitting around, the fewer fires you have. Clean, well-kept areas reduce risk. That’s outside our direct remit, but it affects how effective the system can be.

What challenges make waste and recycling sites difficult to protect compared with other industrial environments?

Russell: It starts with a clear brief in terms of what the system is expected to achieve. What’s driving the requirement? Some customers have identified a process risk or asset and want extra protection beyond insurance. Others are entirely Environment Agency (EA) led and need Fire Prevention Plan (FPP) sign-off or a permit variation. Sometimes it’s a new build driven mainly by insurance requirements. Often it’s a combination of these factors. We’ve built a process to make sure we all mutually understand and document the brief, the customer understands what we’re providing and they understand their obligation to take that proposal to the AHJ. In the past, clients have often pushed ahead, spent a lot of money, then shared it with insurers or the EA at the end of the process only to be told it wasn’t in line with their expectations. We work to avoid that by getting everyone aligned early on what the system is expected to do, what sign-off is required.

James: Standards can be straightforward in some industries, but in waste and recycling there often isn’t a directly applicable standard for specific processes associated with certain MRF operations and materials. We can provide or integrate with a BS 5839‑compliant fire alarm system, but beyond that, who sets the spec? Often it’s a mix of the EA requirements around the FPP and insurer expectations. Insurers are reluctant to write a specification for a waste site, so the client has to own it. We always start from a robust baseline: backup pump (often electric / diesel), UPS battery backup for deluge valves and for the detection system and associated fault monitoring. If power or water is lost, our system can operate standalone. We don’t rely on an internet/network connection for sole system functionality. We can dial in and view cameras remotely with alarms and faults monitored by an alarm receiving centre with key‑holder protocols, but the core system remains fully functional in worst case scenarios.

What role does multidetection technology play in improving early fire identification and incident management?

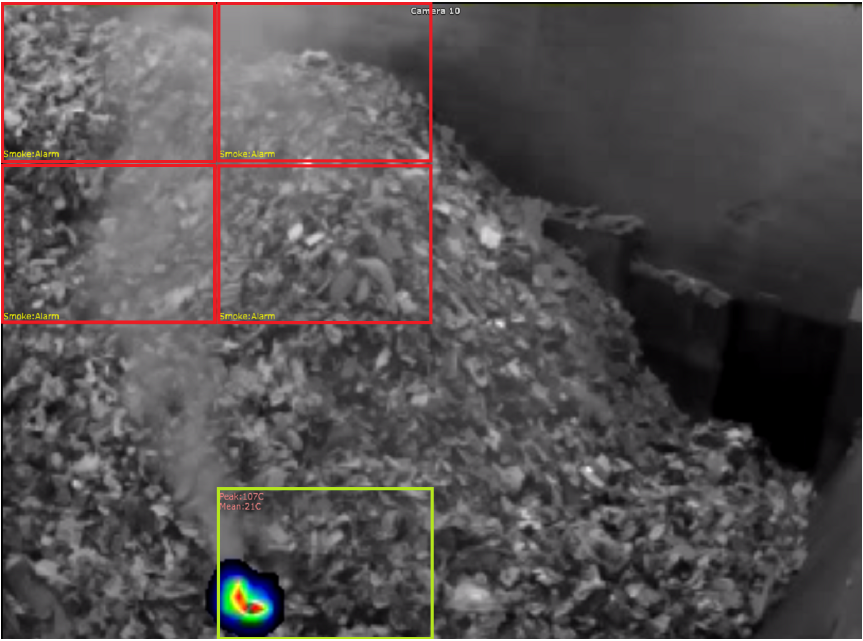

James: Our video flame detection and multi‑detection units can form part of a compliant fire alarm system. We can look to detect for various fire types, which we can configure per site: thermal imaging, video flame detection and video smoke detection. The flame function is verified by the heat function to cut false activations from solar reflections. The video smoke detection can provide very early warning in optimal applications. In facilities with storage of loose materials you can often get a lot of smoke before heat or flame is present so it gives very early warning, especially out of hours with camera-based smoke detection being able to pinpoint locations in a way aspirating systems can’t. When detection occurs, the Alarm Receiving Centre (ARC) is alerted and follows the protocol with up to eight keyholders. Some ARCs review cameras for clients; others have the client review and decide response. commissioning and documented – that’s where the value is.

How do you ensure reliability and performance are maintained after system installation?

James: We choose hard-wearing components built to last, install them to a high standard and set them up correctly. We have a dedicated maintenance, service and callout team. We emphasise the client’s responsibilities under manufacturer guidelines: minimum twice-yearly servicing by our specialist engineers, plus daily and weekly on-site checks – no fault lights on panels, pressures where they should be, pumps checked and so on. We don’t gatekeep. Our fire alarm panels are open protocol. We offer cost-effective SLAs and don’t tie people into expensive contracts. We keep critical stock in our UK facility. We can diagnose many issues remotely so we aim to arrive with the right part and minimise downtime wherever possible. These sites can’t stop, so response time and keeping systems healthy is key Relevant maintenance and aftercare services are outlined on our fire suppression systems page, where clients can request ongoing support and spare‑parts coverage.

What developments will have the greatest impact on the future of automatic detection and suppression?

Russell: We’re seeing much more engagement with local authorities, fire services and insurers. Early on it was hard to get people to understand what we were doing; now our approach is more widely accepted. Manufacturers are improving agents for performance and environmental profile. Accelerating progress in AI means systems be far better at identifying fire risks earlier and reducing false positives.

James: Long-established practices are shifting as the waste stream changes. More batteries and contamination mean more unknowns. People are moving toward newer technologies that are now proven and increasingly more widely accepted to offer a viable solution for recycling and waste to energy. We design with multiple detection cameras across the identified risk areas to avoid single-point failure and blind spots. Everything is fault-monitored, so a camera fault raises an alarm. Configuration is site-specific.

How do foam cannon systems contribute to your wider automatic suppression strategy?

Russell: The foam cannons we use are built to high standards, originally proven in sectors like offshore oil and gas, so they’re robust enough for humid, dusty, dirty environments. They’re manufactured to international standards and third-party accredited. The real difference is how the system is designed to work with the chosen detection medium and the cause-and-effect we agree with the customer. What happens at detection, what areas are protected, how it’s proved at commissioning and documented—that’s where the value is.

How do you ensure reliability and performance are maintained after system installation?

James: We choose hard-wearing components built to last, install them to a high standard and set them up correctly. We have a dedicated maintenance, service and callout team. We emphasise the client’s responsibilities under manufacturer guidelines: minimum twice-yearly servicing by our specialist engineers, plus daily and weekly on-site checks – no fault lights on panels, pressures where they should be, pumps checked and so on. We don’t gatekeep. Our fire alarm panels are open protocol. We offer cost-effective SLAs and don’t tie people into expensive contracts. We keep critical stock in our UK facility. We can diagnose many issues remotely so we aim to arrive with the right part and minimise downtime wherever possible. These sites can’t stop, so response time and keeping systems healthy is key. What developments will have the greatest impact on the future of automatic detection and suppression?

Russell: We’re seeing much more engagement with local authorities, fire services and insurers. Early on it was hard to get people to understand what we were doing; now our approach is more widely accepted. Manufacturers are improving agents for performance and environmental profile. Accelerating progress in AI means systems be far better at identifying fire risks earlier and reducing false positives. James: Long-established practices are shifting as the waste stream changes. More batteries and contamination mean more unknowns. People are moving toward newer technologies that are now proven and increasingly more widely accepted to offer a viable solution for recycling and waste to energy.

Contact Us Today

If you’re looking to strengthen fire protection in a high-risk environment, our team can help. Get in touch with Fire Shield Systems to discuss tailored detection and suppression solutions built around your site’s specific risks and compliance requirements.